The AMPL Platform™

Push/Pull Ascending Airflow System

At Agricultra, we have developed the AMPL Platform™, a revolutionary solution for optimal environmental conditions in indoor farming. Our Push/Pull Ascending Airflow System effectively manages the byproducts of photosynthesis, heat generated by grow lights, and reduces evapotranspiration, enabling a wider variety and larger scale of crops to be grown indoors.

Our Plant First™ approach and expertise in CFD (Computational Fluid Dynamics) modeling have allowed us to recognize the critical importance of airflow in vertical farming. Optimized air management is fundamental to the success of large-scale vertical farming, and at Agricultra, we have dedicated over five years to solving airflow management issues in commercial grow facilities. The result is the patented AMPL Platform and its innovative Push/Pull Ascending Airflow System.

Airflow is Vital to Plant Health

Everything that a plant needs to thrive is governed by air control.

Water & Nutrients: A difference in pressure between water vapor within leaves and their ambient atmosphere enables plants to absorb water and nutrients through their roots. Without proper climate conditions, nutrients and water cannot be delivered to cells.

Optimal Gas Exchange: To maximize a plant’s ability to draw C0₂ and expel oxygen, plants require a dynamic balance of temperature, humidity, and air velocity.

Light: Without sufficient CO₂, photons are wasted which reduces the efficiency of grow lights.

A Mold & Pathogen Free Environment: Stagnant air provides ideal conditions for mold and pathogens that can cause disease.

AMPL™ Masters Airflow with Push/Pull Ascending Airflow

Treated Air is Pushed Upward

Conditioned, C0₂ enriched air is delivered to the base of each plant and pushed through the canopy equally down the length of each production layer.

Ascending airflow also reduces the often-overlooked issue of excess humidity caused by air movement over grow mediums

(Fig. 1). Reduced evapotranspiration results in less energy spent on dehumidification and eliminate grow medium parching.

Fig. 1 Horizontal and Descending vs. Ascending Airflow

Spent Air is Pulled Upward

Inter-canopy ducts remove the by-products of photosynthesis and problematic heat generated by grow lights directly at their source, removing spent air before it can degrade the surrounding environment. By abandoning the concept of spent and conditioned air mixing we have eliminated microclimates and overcome the environmental limitations of multi-layer canopies grown indoors.

CDF Modelling has proven that multi-tier systems that do not remove excess heat and humidity at the canopy level experience accumulated environmental effects due to the unavoidable fact that hot air rises. Understanding and exploiting this fact leads back to our second design principle – Don’t fight physics. It’s inefficient.

Naturally occurring phenomena can be leveraged. Push/Pull Ascending Airflow takes advantage of the natural buoyancy of heat generated by grow lights, ascending airflow reduces CFM requirements, and does not decimate leaf boundary layers with high-velocity airflow required by horizontal and descending airflow methods at scale.

AMPL Precision Airflow Nozzles

Automotive-grade precision airflow nozzles can be adjusted to compensate for the unavoidable pressure drop that occurs as pressure changes down the length of a duct.

Custom nozzles and combinations of nozzles can be developed to:

1. Satisfy specific plant requirements

2. Achieve specific project goals

3. Achieve specific airflow patterns

CFD Model of Airflow Nozzle Combination

CFD model of balanced air velocity in an eight-layer AMPL Pro system (Side View).

Balanced Airflow has an Extraordinary Impact on Sensor Data Quality

By eliminating microclimates, sensors data quality can be far better relied upon to make meaningful decisions during production to adjust for crop variability and a grower’s ability to develop proprietary expressions of common genetics.

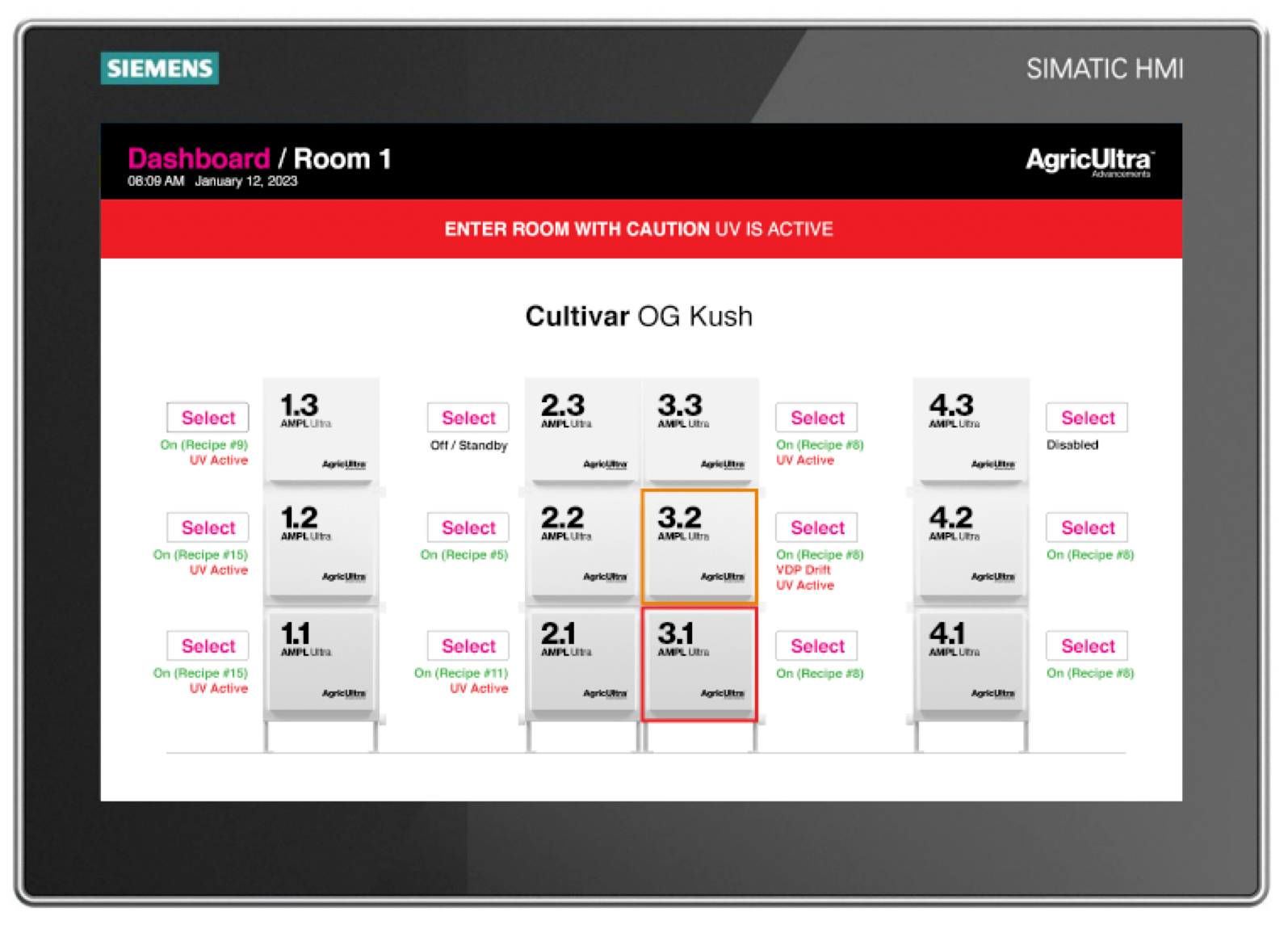

AgricUltra Advancements customizes human-machine interfaces (HMIs) for clients to match control and data collection requirements.

Optional Data Collection Points

• Plant Health

• Visual Imaging

• VDP

• Transpiration

• MicroCoil Efficiency

• Reheat Coil Temp

• Cooling Coil

• Relative Humidity

• Comparative Temperature

• Realtime Biomass

• Lighting Efficiency

• RHC / CC Temp Delta

• Fan Speed

• Irrigation Flow

• PH

• Nutrient Uptake

• QA

• Product Traceability

Please Note: Options vary depending on AMPL Model

AMPL Automated Plant Factory

The AMPL Platform integrates with widely adopted warehouse logistics systems without interfering with environmental systems; a result of our patent-pending Push/Pull Ascending Airflow system. This reduces the cost of automation and added the assurance of implementing the same systems used by some of the biggest companies in the world.

With AMPL’s ability to stack virtually unlimited canopies, warehouse automation has been an important design consideration. We have developed a robotic plant handler that attaches to third-party automated logistic systems to be used for a wide range of applications.

AMPL Technology is Available in Three Models

AMPL Ultra™

An Independent Hydronic MicroCoil Based System

AMPL Ultra offers the ultimate in environmental control, energy management and flexible production. Independent MicroCoils turn each layer into its own growing environment, enabling growers to match output to market needs. AMPL Ultra is even capable of growing different crops on different layers**. Hydronic technology also eliminates the need for bulk air ducts, simplifying facility design. AMPL Ultra is an elegant solution for pharmaceutical horticulture and large-scale plant factories with unique output requirements.

AMPL Pro™

A Bulk Air Based Environmental System

AMPL Pro utilizes controlled bulk air diffusion and directed inter-canopy bulk air conditioning. This is the most cost-effective means of implementing Push/Pull Ascending Airflow in high-volume plant factories pending production goals or small to medium size grow rooms intended for vascular plants with high environmental requirements.

AMPL Sprout™

Turn-Key Research & Product Development System

AMPL Sprout™ is a small-scale hydronic MicroCoil based grow system. It is a more cost-effective option for educational institutions than traditional research grow chambers. When used as a product development tool in commercial facilities, R&D scales seamlessly to AMPL Pro and AMPL Ultra systems.