The AMPL Pro Bulk Air Based Precision CEA System

Existing methods of vertical farming drastically underestimate the importance of airflow – Optimized air management is fundamental to the success of vertical farming at scale. Without proper airflow, plants cannot transpire to absorb nutrients or exchanges gasses required to perform photosynthesis. For plants to thrive they require a dynamic balance of air temperature, air velocity, and air moisture – the three factors that determine VDP. The biggest challenge facing indoor growers is microclimates created by uncontrolled airflow that negatively affect VDP.

Solving the pervasive issue of microclimates required a shift in conventional thinking. Traditionally, lateral, or descending fans are used to homogenize conditioned and unconditioned air while disrupting microclimates caused by uncontrolled bulk air entry and heat generated by lights; a strategy called bulk air mixing. With high-intensity lighting for higher-order plants or an increased number of lights in lower-order plant factories, these issues quickly compound.

Three fundamental factors must be solved to achieve achieving a stable environment; controlling bulk air entry, eliminating bulk air mixing, and consistent delivery of conditioned air to every plant. AMPL Pro eliminates microclimates with a holistic approach to room-level and canopy-level airflow.

Our patented Push/Pull Ascending Airflow System and Bulk Air Diffuser technology form a highly efficient means of implementing precision airflow in high-volume plant factories and small to medium-size facilities that aim to maximize real estate without sacrificing climate quality or control.

AMPL Pro also facilitates precision control of inter-canopy airflow in legacy DX bulk-air room applications.

The AMPL Platform is patented.

Supported Grow Styles

• Hydroponic Drip Irrigation

• Aeroponic

• Living Soil Drip Irrigation

• Aquaponic

NOTE: Multiple levels of control are possible.

Integrated Systems

• Airflow

• Irrigation

• Lighting (System Agnostic)

• Sensors (System Agnostic)

• Control Software

• Logistics Integration (Possible via ModBus, BackNet or 0-10v)

How AMPL Pro™ Works

AMPL Pro takes a holistic approach to airflow management that addresses room-level and canopy-level airflow.

Our Bulk Air Diffusers slow down and evenly distributes airflow bulk air entry as it is directed to the AMPL Pro canopy level airflow management system.

The AMPL Pro Bulk Air Diffuser is built to automotive-grade specifications. Its modular components can be adapted to any room geometry.

Patent-pending Push/Pull Ascending Airflow directs conditioned air upward through the canopy with crop-specific nozzles that compensate for the unavoidable pressure drop that occurs in supply ducts.

Inter-canopy return ducts direct spent air to a bulk air return duct to eliminate bulk air mixing.

Solutions are CFD tested before installation.

The Benefits of Balanced Push/Pull Ascending Airflow

Balanced Push/Pull Ascending Airflow eliminates Microclimates.

Each plant receives pure, unmixed, conditioned air.

By removing problematic heat and humidity on every layer there is no theoretical limit on layer stack heights. AMPL layer stack heights are only limited by logistics and local by-laws.

AMPL reduces the volume of air that must be treated compared to grow systems that rely on spent/conditioned bulk air mixing. This gives growers tighter climate control and improves dynamic response times while lowering operating costs.

Stagnant air lower conducive to mold low in the canopy is disrupted reducing the need for chemical intervention.

Layer level climate control requires treatment of a smaller volume of air compared to room level air treatment.

Canopy layer-level environmental control also allows maintenance to be localized to limit downtime.

High-velocity air moving over lighting fixtures improves passive cooling which maximizes LED diode lifespans.

Reduced grow medium parching and excess humidity caused by lateral or descending airflow evapotranspiration.

Balanced airflow significantly improves sensor data.

This is what precision airflow looks like.

CFD Model of Balanced Air Velocity. AMPL Pro with AgricUltra Advancements’ Bulk Air Diffuser (Side View)

CFD Model of Balanced Air Velocity. AMPL Pro with AgricUltra Advancements’ Bulk Air Diffuser (Top View)

NOTE: The canopy level

airflow shown does not accurately reflect our actual nozzle air projection angle due to the limitation of Cartesian CFD modeling. Actual air projection will exit nozzles at 45° resulting in optimized turbulent ascending airflow.

CFD Model of Balanced Air Velocity. 8 Layer AMPL Pro Plant Factory Application (Side View)

Balanced Airflow has an Extraordinary Impact on Sensor Data Quality

CFD of Balanced Temperature with Sensor Placement

By eliminating microclimates, sensors data quality can be far better relied upon to make meaningful decisions during production to adjust for crop variability and a grower’s ability to develop proprietary expressions of common genetics.

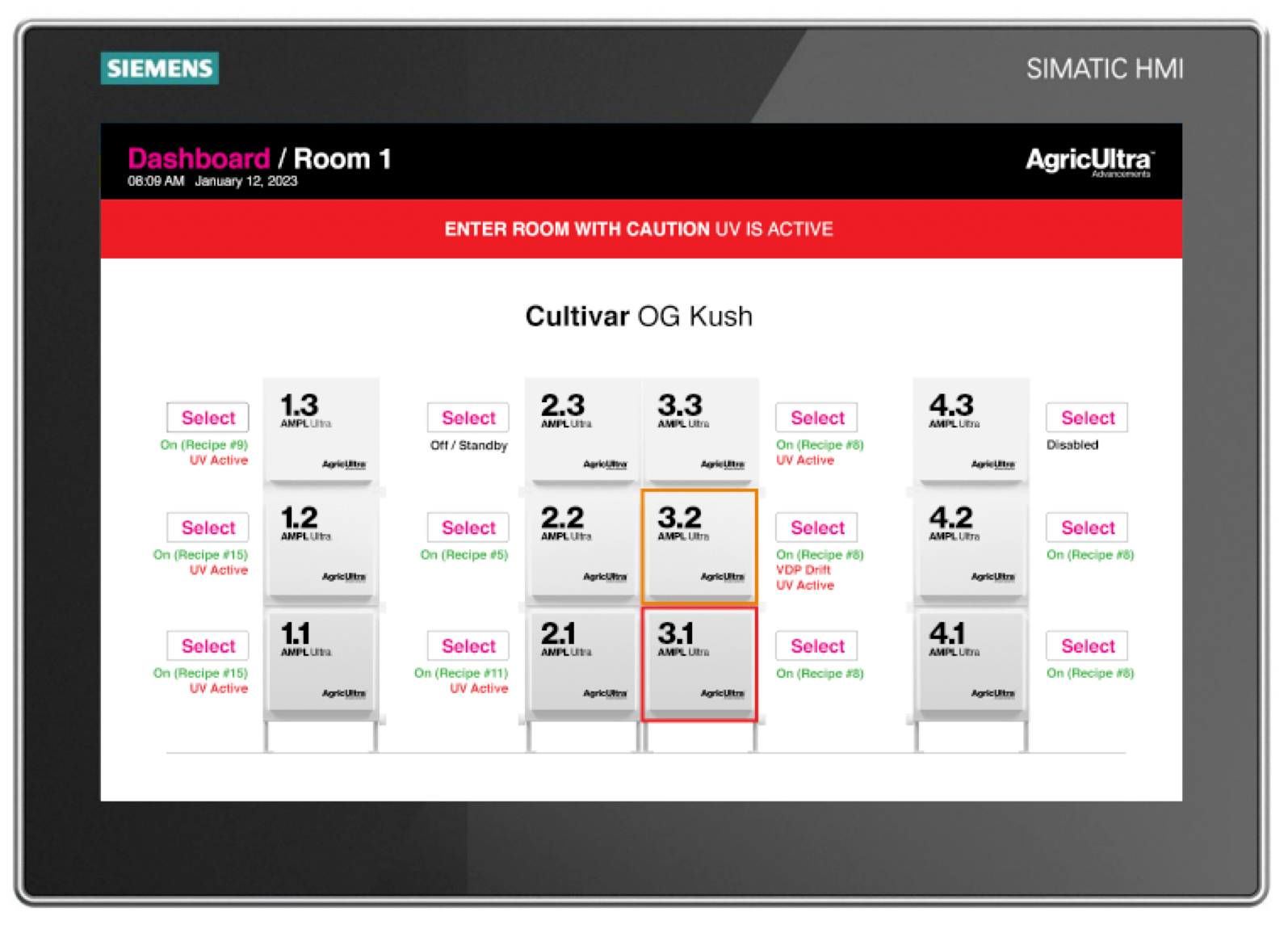

AgricUltra Advancements customizes human-machine interfaces (HMIs) for clients to match control and data collection requirements.

Data Collection Point Options

• Plant Health

• Visual Imaging

• VDP

• Transpiration

• Relative Humidity

• Comparative Temperature

• Real-time Biomass

• Lighting Efficiency

• Fan Speed

• Air Velocity

• CO₂ Concentration

• Irrigation Flow

• PH

• Neurite Uptake

• QA

• QR Code Product Tracing

System Control

AMPL™ OS comes standard with our own fully integrated PLC based control system. We do not need the assistance or help from a Building Automation System or Third-Party control system to maintain control in any layer or row for any of the following:

• Canopy Temperature

• Canopy Humidity

• Canopy VPD

• Canopy Air-Velocity

• CO2 control

• Irrigation control

• Multi-Channel Light Control

Note: Some features are limited by chosen features and legacy equipment capabilities.

AMPL™ OS can also output this data via ModBus, BackNet or 0-10v which allows the AMPL platform to easily be connected to other automation systems.

AMPL™ OS allows remote access to view the status of alarms, view setpoints or change setpoints.

AMPL™ OS outputs real-time data streams of the measured variables to track and optimize grow particulars or compare the results of different grow cycles.

AMPL™ OS facilitates control/grow customization with the ability to add additional sensor suites such as Par Sensors and Leaf temperature sensors to further optimize the grow conditions and the resultant yields.

The future of the AMPL Platform is bio responsive feedback. At a point in the very near future, AMPL’s conditions will automatically adjust to plant needs.

We can provide FanCoil based bulk air solutions that realize a 30 to 50% reduction in energy costs.

vs. DX air handlers. Reduction realized is dependent upon set point

conditions, type of lights used, and chiller type.

Optional Grow Curtains

AMPL™ can host the addition of reflective curtains to increase dynamic response times and reflect otherwise stray photons back into the canopy where they belong and minimize air bleed. An added bonus of the curtains is that they also keep the treated air focused on plants. Curtains are hung from grommets so they can be easily maintained. Roller blinds can be developed.

Lighting Instruments

AgricUltra Advancements™ specializes in multi-channel dimmable lighting for photosynthesis, photomorphogenesis, and pathogen and pest control used to reduce or eliminate chemical intervention. Our flexible lighting system allows growers to achieve their desired PPFD by varying the number of lights above each canopy. Smaller format lights minimize the cost of eventual fixture failure compared to multi-rail lighting fixtures.

Our photosynthetic, dual spectrum, cool white + deep red SolarRail™ lights can be combined with our deep UV MetaRail™ grow lights as needed. We have separated our photosynthetic spectrum from our UVB+A lights to provide further agency to develop specific spectral strategies.

The MetaRail™

Supplemental UVA+B LED

Lighting

Instrument

The SolarRail™

Cool White+Deep Red LED Lighting Instrument

The MetaRail™ is a two-channel, dimmable UVB and UVA LED lighting instrument that is capable of improving the taste, texture, smell, potency, and resilience of plants while controlling mold and pests.

Learn more about the MetaRail.

With multi-channel dimming, the SolarRail gives growers the ability to deliver just the right balance of light during every stage of growth.

Learn more Learn more about the SolarRail.

Note: The AMPL™ Platform can be used with lights from other manufacturers, only limited to LED fixtures with similar form factors (below 4’ in length) that are dimmable and external drivers.

Offset HVAC Loads with UV

By incorporating Deep-UVB lighting strategies with our approach to HVAC deployments it is possible to significantly reduce operational electrical loads. This can be achieved because UVB kills mold and mildew while increasing some plant’s natural ability to fight pathogens. In an AMPL™ Platform, upward airflow further minimizes the possibility of mold and infestation on the bottom of leaves while direct exposure UV light controls mold and insects on top. This provides the grower agency to elevate the temperature and humidity setpoints thus lowering the loading on the Chiller/HVAC system.

Learn More about UVB+A Pathogen Control

UVB treated strawberries after 9 days in cold, dark storage.

Strawberries after 9 days in cold,

dark storage control

Seamlessly Scale Research to Production

Scaling research from laboratory conditions to large-scale production poses a challenge to producers because test conditions do not match production environments. This is not the case with the AMPL Platform.

Conditions can be consistently translated from our small-scale AMPL Sprout R&D unit, from AMPL Ultra production layers, or between any AMPL Platform facilities.